Every year, more than 20 million square meters of sandwich elements are produced for the construction sector in Germany, and as many as 200 million in total in the European Union. There is potential for savings in materials and energy by optimizing production processes. To promote resource-efficient production of sandwich elements, the German Federal Ministry for Economic Affairs and Energy has launched a new research project called “Resource-efficient sandwich elements through non-destructive monitoring for lightweight construction ReSaMon.”

Sandwich elements consist of two thin metallic face sheets and a core of rigid polyurethane foam and are important building products. However, potential weak points such as damage due to heat-induced stresses are not always detectable in the manufacturing process and only appear during processing on the building site. This leads to complaints, longer construction times and other problems.

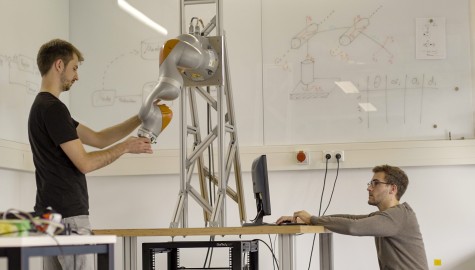

The “ReSaMon” project team will develop a new non-destructive ultrasonic measurement technique that can immediately detect flaws and inaccuracies to identify potential weak points and changes in material properties during the production process. The measurement technology works without contact and therefore does not interfere with the production process. The construction industry and end users will benefit from this technology.

The project consortium consists of industry partners, sandwich panel experts, metrology specialists and simulation experts who are bringing their expertise together to achieve a better understanding of the influences of production on product properties. The project partners include the Fraunhofer Institute for Structural Durability and System Reliability LBF, the Institute for Steelwork Technology IFSW, the company Inoson, manufacturers such as ArcelorMittal and Covestro Deutschland, and us, the Measurement and Sensor Technology (MuST) department at TU Darmstadt as a research partner focusing on ultrasonic measurement technology.