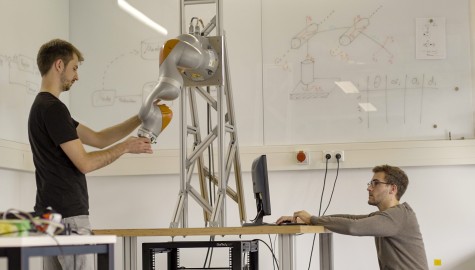

This research project focuses on the acoustic levitation of liquid droplets using ultrasound. A novel method enables the vertical positioning and movement of droplets, even against gravity, solely through the targeted control of a commercially available ultrasonic transducer. This contactless technique also operates across obstacles and offers sterile manipulation capabilities.

The project's objective is to experimentally and numerically demonstrate the controlled movement of liquid droplets. Numerical models and simulations are essential to understanding the complex dynamics and conducting experiments efficiently under various conditions.

The project is being conducted in collaboration with the MMA research group led by Prof. Dr. Dieter Bothe at TU Darmstadt. It combines expertise in acoustics, measurement technology and numerical analysis to establish the foundation for innovative, contactless manipulation methods for liquid droplets, paving the way for a wide range of applications.

This research is funded by the DFG (No. 542327521).