Building bridges—with 3D printing in mid-air

Our new research article in Elsevier’s Additive Manufacturing is online!

2025/11/07 by Alexander A. Altmann

Researchers at Measurement and sensor technology Group and partners present a simple recipe for printing self-supporting, single-layer polypropylene spans in mid-air that enclose cavities cleanly—and a model to predict the resulting surface quality before you print.

Building bridges—in a special way: 3D printing in mid-air that cleanly seals cavities

Bridges matter—especially now. Our team shows how to print self-supporting, single-layer polypropylene spans in mid-air that enclose cavities cleanly on an off-the-shelf printer. We also provide a predictive model so you can pick parameters for the surface quality and bonding you want before you hit “print.”

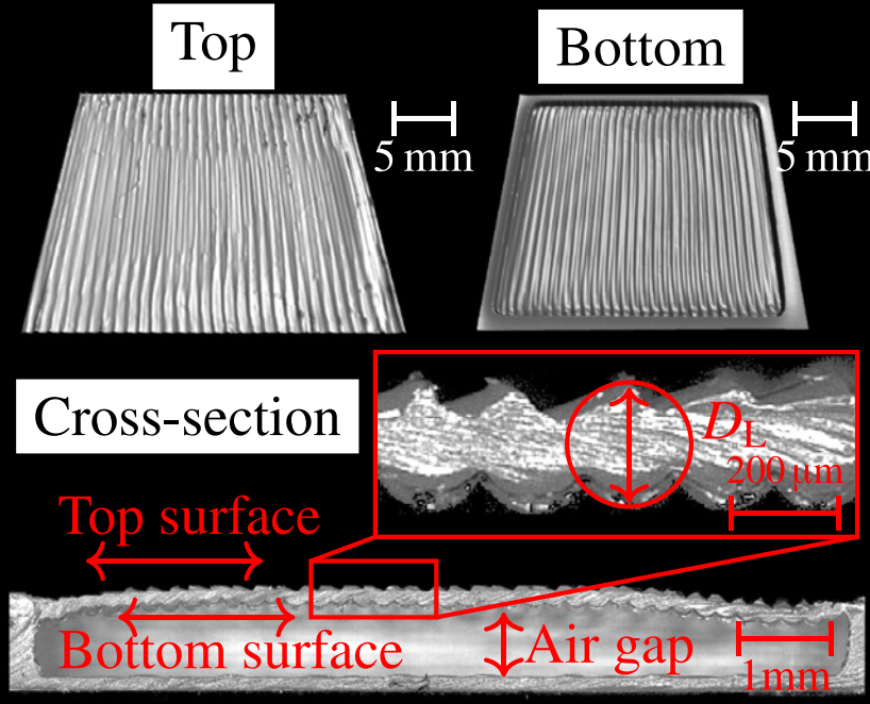

What’s new Predictive model:

- Links flow rate, nozzle geometry, and line overlap to geometry, material distribution, and roughness of a mid-air top layer. It enables forward predictions and inverse parameter tuning.

- Validated on a standard printer: Using a Prusa i3 MK3S+ and PP, the team varied flow from 20 to 100 percent at 105 percent overlap to achieve fully closed surfaces without cracks.

- Surface you can dial in: With lower flow, the top “bridge” gets flatter and smoother—down to Ra = 4.52 ± 0.49 μm at 20% flow—while higher flow introduces waviness.

Why it matters

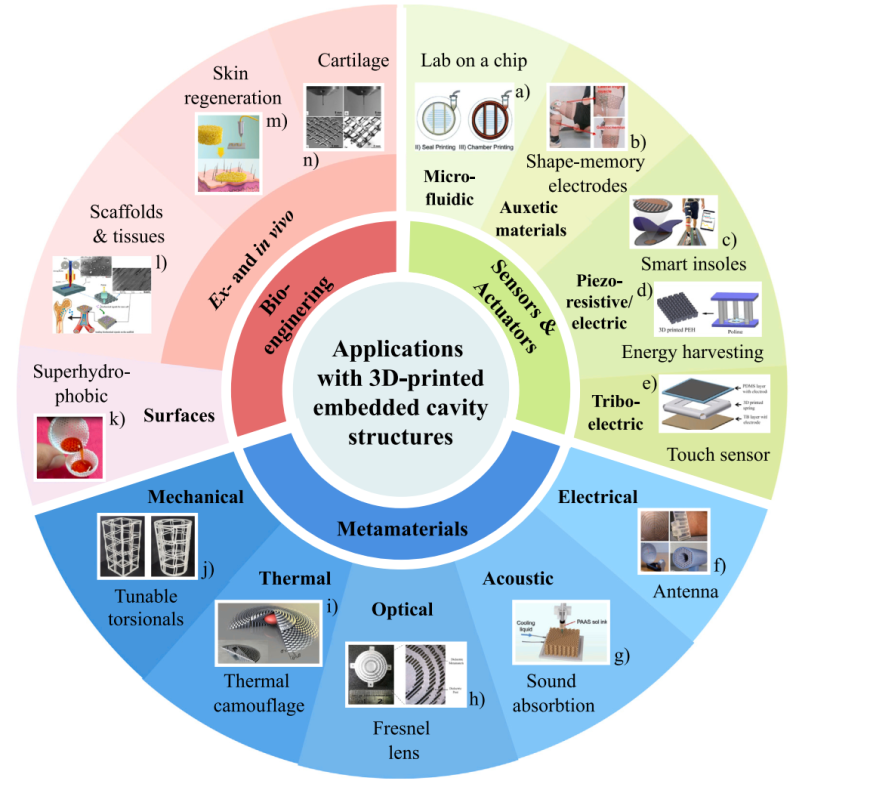

Enclosed air cavities are functional building blocks for microfluidics, sensors, and lightweight metamaterials. A mid-air, single-layer approach reduces stiffness and still achieves airtight closure with strong intralayer bonding (up to ~70 percent), enabling compact channels and sensitive membranes.

How to use it

1. Set overlap to ~105% for sealed surfaces,

2. choose a zigzag path with constant spacing,

3. lower flow (≤60%) to suppress roughness peaks via nozzle-induced smoothing, and

4. use the model to target a desired Ra or bonding level.

Paper details

The paper, titled “Self-supporting mid-air 3D printing of single-layer polypropylene structures: Flow rate-dependent analytical modeling and surface characterization,” appears in Elsevier’s Additive Manufacturing, Volume 113, 5 September 2025, 105010.

Link

Read the paper: Link

Citation

Altmann A. A., Suppelt S., Wüst P., Dörsam J. H., Latsch B., Flachs D., Blaeser A., Zhang X., Thielemann C., von Seggern H., Kupnik M. Additive Manufacturing, 113 (2025) 105010.