New Research Publication: Non-Contact Ultrasonic Stress Measurement with Lamb Waves

A novel, non-contact method for ultrasonic stress measurement in sandwich panels using Lamb waves enables precise, localized, and efficient evaluation of mechanical stress.

2025/05/16

The MUST group in collaboration with partners from Fraunhofer LBF, University of Antwerp, and industry, have published a groundbreaking study in NDT&E International titled “Non-contact ultrasonic stress measurement using Lamb waves”.

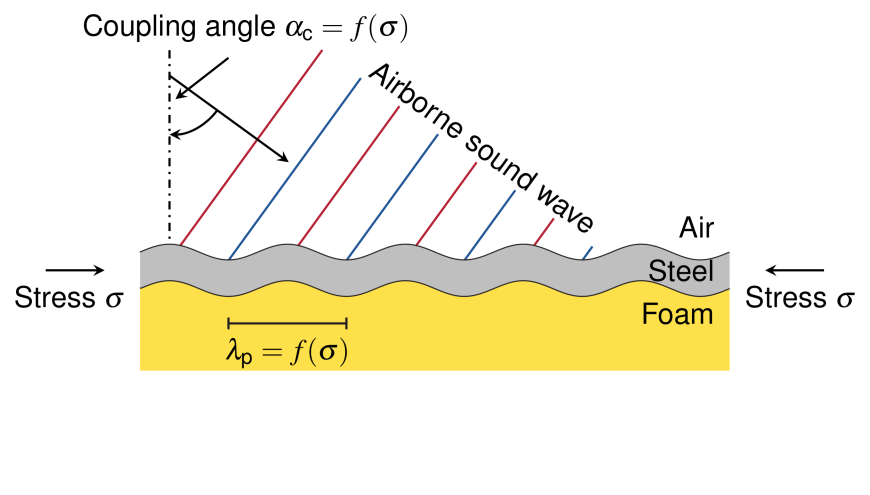

The team presents a novel method for measuring mechanical stress in materials using air-coupled ultrasound, completely without physical contact. By analyzing the coupling angle of ultrasonic Lamb waves in steel sandwich panels, stress can be inferred with high precision—offering a promising alternative to conventional strain gauges.

This method not only increases measurement speed and repeatability but also enables online monitoring during manufacturing processes. The researchers combined simulations with full-scale bending tests on commercial sandwich panels, confirming the accuracy of their coupling angle approach. Their results suggest that combining this with traditional transit-time methods enhances reliability and provides both localized and average stress data.

This innovation opens new avenues for stress monitoring in aerospace, civil engineering, and quality control in material manufacturing.