International team recycles e-car batteries

Recycling lithium batteries – and still ‘reLiable’

2023/01/12 by Anja Störiko

Electric car batteries last around eight to ten years – after which their charging capacity drops to below 80 per cent, which is too low for electric car operation. The remaining high capacity is utilised by a young team of founders as an electricity storage system, for example for photovoltaic systems. They have developed an intelligent battery management system that extends the life of the battery by a further eight to ten years. reLi, the name of their start-up, says it all: recycling lithium batteries – and making them ‘reLiable’.

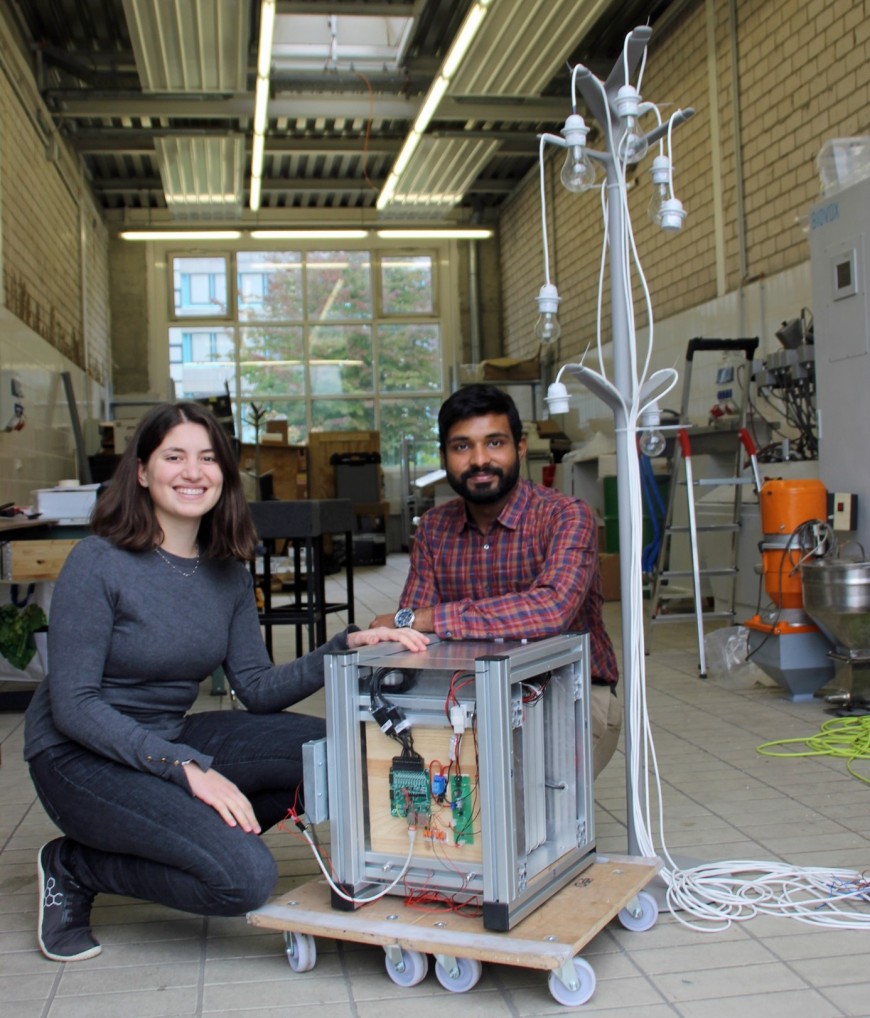

As an international team, three students are realising this idea together: Italian Laura Laringe (24) studied in Naples, Barcelona and Stockholm, where she completed her Master's degree in sustainable energy technology. In 2019, she met Krishna Rathinam (25) from India, who was studying in the Netherlands and Sweden and was now writing his Master's thesis at a company in Stockholm. A year later, Ashish Baskar (26), also from India, joined them. The three of them realised that they had the same idea: ‘We felt it was a problem and a waste to dispose of batteries from electric cars that were actually still in good working order,’ says Laura. After analysing the market, they decided to come to Germany to realise the vision they had developed in Sweden: ‘The market is simply bigger there. Thanks to the Unite! network, a European tech university alliance, they made contact with TU Darmstadt from Stockholm's Royal Institute of Technology (KTH).

We felt it was a problem and a waste to dispose of batteries from electric cars that were actually still in good working order.

Sabine Remmert from HIGHEST was a great help to us,’ emphasises Laura. She organised a workplace at the start-up hub HUB31 in Darmstadt, supported by the Lab3 association: ‘That was anything but a matter of course, because the three of them were no longer students at the beginning, but also not yet founders with funding,’ says Remmert. The start-up management team at TU Darmstadt provided support with expert contacts, the further development of the business model and the application for EXIST funding from the Federal Ministry of Economics and Climate Protection, including the complicated visa applications. Finally, the team was able to post: ‘We are proud to announce that we will be funded with an EXIST start-up grant from August 2022’. They have 125,000 euros at their disposal for one year.

An intelligent control system

Discarded electric car batteries are still far too good to dispose of, explains Ashish: ‘We have developed an intelligent control system that utilises the remaining capacity optimally and safely. He unscrews the prototype, a container the size of a drinks crate that contains several plates – individual battery components. Unfortunately, all vehicle manufacturers use their own battery types of different sizes and chemical compositions, so reLi has so far favoured using cells from a single car company, even though the system works for all battery types.

reLi is a great team: international, intercultural, interdisciplinary, open, committed and hard-working.

Sabine Remmert, HIGHEST

The real ingenuity is hidden in the inconspicuous switching elements around the battery plates: they control the charging status of the battery elements and thus make optimum use of the storage capacity. The small entry-level model is suitable for temporarily storing energy from private photovoltaic systems. ‘However, we can also easily build and control larger units that are suitable for large PV systems and, above all, make ideal use of fluctuating energy prices,’ explains Ashish. He is certain that such storage systems will become increasingly important in order to optimally utilise the electricity grid as part of the energy transition. There are similar approaches elsewhere – ‘but our system is smarter than others,’ says Laura confidently. The software and hardware enable optimal utilisation and control.

reLi storage systems cost only 60 per cent of a corresponding new battery. At the same time, CO2 emissions are 90 per cent lower because the materials are reused. ‘We are extending the service life by a further ten years – a period that will hopefully be utilised to enable a truly circular battery system by then,’ says Ashish.

Future prospects

The next step for the team is to install test storage units in households. Later, they also want to build larger systems for more specific applications and gradually expand their activities throughout Europe. But first, the team needs to be expanded: ‘We need engineers, business people – and a good command of German,’ smiles Laura.

The difficult start, the joint choice of location and the many uncertainties regarding residence status have been mastered well thanks to the support, says Ashish. Laura adds that she has learnt a lot – and: ‘I now know that this is exactly what I want to do: work independently, with a meaningful goal’. The added value of their work for society is important to all three of them.

Always up-to-date with exciting news from the etit campus: Follow us on Instagram!

Recommended external content

We have selected external content from Instagram for you and would like to show it to you right here. To do this, you must reveal it with one click. You can hide the external content at any time with another click.

I agree to external content from X being shown to me. This may result in personal data being transmitted to third-party platforms. You can find more information in our Privacy Policy.