Ink instead of diodes

The TUDa start-up MimoSense develops film sensors in a class of their own

2024/05/23 by Heike Jüngst

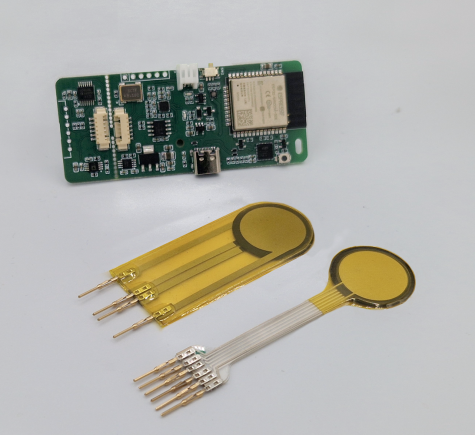

They are highly sensitive, reliable and widely applicable: the patented foil sensors from MimoSense make it possible to measure small forces such as touch, pulse, breathing and the smallest vibrations of any kind. But even large forces, such as those that occur on scales or on the blades of wind turbines, can be precisely recorded by these wafer-thin electronic marvels. Omar Ben Dali, Romol Chadda and Stefan Trillig are now receiving funding from the German government's EXIST research transfer programme. They want to use these funds to develop their foil sensors into market-ready products. Large companies have already come knocking.

HIGHEST: Omar, Romol, you studied electrical engineering and information technology at TU Darmstadt and developed a new class of foil sensors during your doctoral thesis. What makes these foil sensors different from conventional ones?

Omar: We are actually often asked what the difference is to the foil sensors in smartwatches, for example. They also measure steps or bodily functions such as pulse and heart rate. The sensors in smartwatches, however, measure optically. MimoSense foil sensors, on the other hand, measure forces via the smallest movements and vibrations. They are like an electronic skin. Unlike all other sensors, they can simultaneously measure both dynamic and static forces, even through thick layers such as a mattress.

Romol: A practical example: our multimodal foil sensors have real added value, for example for the healthcare sector. You can place one of these ultra-flat sensors under a mattress and it measures various vital signs of the person lying on it. Or in an ambulance. You no longer have to place electrodes on the patient's body to monitor their heart rate. Our sensors perceive their surroundings in a similar way to the human skin. And just as our senses pass the information on to the brain, our film sensors also pass the collected data on to a data processing system in order to analyse it. In the example above, relevant information on pulse and breathing would ultimately be obtained without the body having to be extensively wired up.

Stefan: MimoSense foil sensors can be used on surfaces of almost any shape. They are so flexible because they consist of very thin plastic films on which conductive ink tracks are printed. We have identified more than 50 use cases. MimoSense films have the potential for a wide range of applications and markets – from robotics, Industry 4.0, IoT, manufacturing machines and predictive maintenance to aerodynamics and fluid mechanics, building technology, wearables, exoskeletons, prostheses and even health care.

HIGHEST: How did it come about that you turned this research innovation into a business model?

Omar: For us in research, it was initially all about overcoming the limitations of the sensors currently available on the market. Once we had succeeded in doing that, Romol and I quickly realised that our invention had great potential for practical applications. And we discovered during many conversations that we could imagine being entrepreneurs ourselves. We didn't want to see our invention disappear into a drawer or leave it to someone else. But, as is often the case with scientists, we were mentally and linguistically stuck in theory. It took a while before we were able to translate the innovation into initial ideas for business cases. In the beginning, we only ever used technical terms, just like at scientific conferences. Nobody from the business world understood us. We were neither practitioners nor business economists. We had to learn that first.

Romol: Last year, we took part in the TU ideas competition with our idea of turning the film sensors into a business model. That was the first public appearance for us at MimoSense and the first really big deadline that mattered. Thanks to the great support and motivation from the HIGHEST innovation and start-up centre, we received constructive and very helpful feedback for our pitch presentation and practice-oriented training. This experience not only helped us personally and increased our visibility, but also showed us how important it is to face such challenges as regularly as possible.

HIGHEST: In the TU 2023 ideas competition, you won the special prize from the Thomas Weiland Foundation for special engineering achievements in research and for the great application potential of MimoSense sensor foils. What happened next for you?

Omar: After our first trade fair appearance at InnoDay 2022, it was already clear to us that we wanted to found a start-up – our doctoral contracts were due to expire at the end of 2023 anyway. We then looked for a co-founder who was familiar with business models, business plans, financing, marketing, etc. We then met Stefan Trillig, who is now responsible for these areas as a co-founder at MimoSense, through a mutual friend who had successfully founded his own company a few years ago.

Stefan: As an industrial engineer in mechanical engineering, I have held many different positions in companies over the course of my career – from company developer to management consultant to board member of a bank. I've been self-employed with a consultancy firm for a few years now and have a great desire to set up a manufacturing company with really tangible products for the first time. In many conversations, I got to know Omar and Romol as very broad and deep-thinking engineers. In addition to their specific expertise in sensor technology, they have also learnt a lot about materials science, printing technology, IT, software development and much more. They have an exceptionally broad network, both at TU Darmstadt and in the region's start-up ecosystem. For me, they are absolute geniuses.

Romol: We also spoke to other business economists, people of the same age that we know from university. The fact that Stefan is much more experienced initially led us to fear that we would be patronised. But that never happened. Stefan didn't tell us what we should or shouldn't do, but instead used his questions to consciously guide us towards business topics and possible solutions. We meet as equals and complement each other perfectly. Stefan picks up on a lot of our expertise, identifies potential areas of application and translates them into business cases.

Omar: My grandfather, an entrepreneur like my parents, always says that ‘wisdom and energy belong together. To run a company successfully, the knowledge of more experienced people should always flow in alongside the drive and vigour of the young.’

HIGHEST: With EXIST funding of around 750,000 euros, you are now launching MimoSense on the market. Quite fast since the TU ideas competition in September 2023.

Stefan: We could have been much faster. We successfully pitched to the EXIST committee in Berlin in December – on the very day that Finance Minister Christian Lindner imposed the budget freeze with immediate effect. That initially put the brakes on everything. We didn't know if and when we would ever receive the funding, although we were informed very promptly that the panel of experts had spoken out in our favour. You can see how quickly and directly big politics can affect even the smallest region.

Romol: We actually wanted to start founding MimoSense GmbH in January of this year. Instead, we had to register as unemployed because our doctoral contracts expired in November 2023. We were living off savings and had to write job applications, the whole German bureaucratic unemployment programme. However, the three of us actively used the time to continue working together on our sensor technology and business plan within our own means.

Omar: The EXIST funding has been flowing for a year and a half since 1 May. We have office space and a laboratory at the university and have been able to hire our first employees – we are currently looking for software developers, printing technologists and sensor technicians – and are very confident that we will soon be able to enter the market.

Stefan: We used the ‘funding-free’ period to identify the value creation steps and potential applications for our multimodal sensors and attended a wide range of trade fairs to speak to potential suppliers, cooperation partners and customers. We have already held preliminary talks on project and product approaches with a number of companies, including various global corporations. MimoSense film sensors have the potential to become a mass market product because they not only replace existing film sensors thanks to their greater sensitivity and versatility, but can also open up many new fields of application. We are firmly convinced of this.

Always up-to-date with exciting news from the etit campus: Follow us on Instagram!

Recommended external content

We have selected external content from Instagram for you and would like to show it to you right here. To do this, you must reveal it with one click. You can hide the external content at any time with another click.

I agree to external content from X being shown to me. This may result in personal data being transmitted to third-party platforms. You can find more information in our Privacy Policy.