Lighter into space

Start-up Metalonn reduces satellite components more than tenfold

2024/07/18 by Anja Störiko

Much more than we realise is controlled by satellites today: from navigation devices and weather forecasts to the transmission of television and the internet, they provide valuable data for our everyday lives. And this is increasing exponentially: ‘In the last three to four years, three times more satellites have been launched into space than existed before,’ says Emrah Fuat Talan, describing this growing market. This is where the start-up Metalonn, which he and Arshad Mehmood founded in mid-2023, comes into play.

Metalonn builds special components for satellites that are lighter and therefore more cost-effective and suitable for mass production. Electrical engineer Mehmood and automation engineer Talan develop high-frequency components specifically for the aerospace industry. ‘With satellites in particular, every gram counts,’ explains Talan. Every extra kilogramme costs up to 25,000 US dollars at launch – so the savings potential is high. Well over 10,000 satellites have been sent into space since 1957, almost half of them in the last two years. ‘The market is growing enormously – and we want to help move from a niche to a mass market,’ emphasises Talan.

The two met at ALCAN Systems, a start-up specialising in antennas with liquid crystal technology. They decided to found Metalonn as a spin-off. ‘So we're not your typical young university graduates,’ says Mehmood, ’but an experienced duo.’ At the heart of their development are sophisticated metal coatings for highly complex moulded parts – hence the name Metalonn, which stands for ‘metal on nothing’ and refers to the hollow material.

At the end of 2023, the start-up received funding from the Business Incubation Centre (BIC) of the European Space Agency (ESA). In addition to funding, they received office space, advice and optional access to ESA laboratories. ‘We believe in our dream – and are investing our own savings,’ says Talan. Their ideas were received with enthusiasm on the market, which gave them additional motivation.

‘Antennas are everywhere these days,’ explains Talan – in mobile phones, cars, aeroplanes and satellites. Modern life is unimaginable without antennas, which form the backbone of all telecommunication systems. They are constantly being developed further: smaller, cheaper, more efficient and lighter. Metalonn wants to conquer the satellite communications market with its cost-effective and lightweight antenna components.

Innovative recipe for ultra-lightweight construction

With their knowledge of materials and processing, the founders of Metalonn develop particularly lightweight antenna components. At half to a third of the weight, they are considered lightweight components; but their ultra-lightweight components weigh as little as a fifteenth. The lightweight materials are extremely valuable for aerospace and aircraft construction. In space travel, the materials are also exposed to extreme temperatures. ‘And they have to withstand shocks like an earthquake during take-off,’ says Mehmood. This hardly seems compatible with lightweight construction. But their knowledge of materials is unique and special. They use computers to simulate and develop the materials, coatings and the entire recipe for the manufacturing process, customised to the applications. Several contractors then assemble the component step by step. ‘Each individual contractor does what they can – but only we have the overall recipe,’ Mehmood reveals the confidentiality strategy. This is based on special materials or polymers that are coated with metals. Depending on the application, Metalonn adapts the recipe using a patent-pending process.

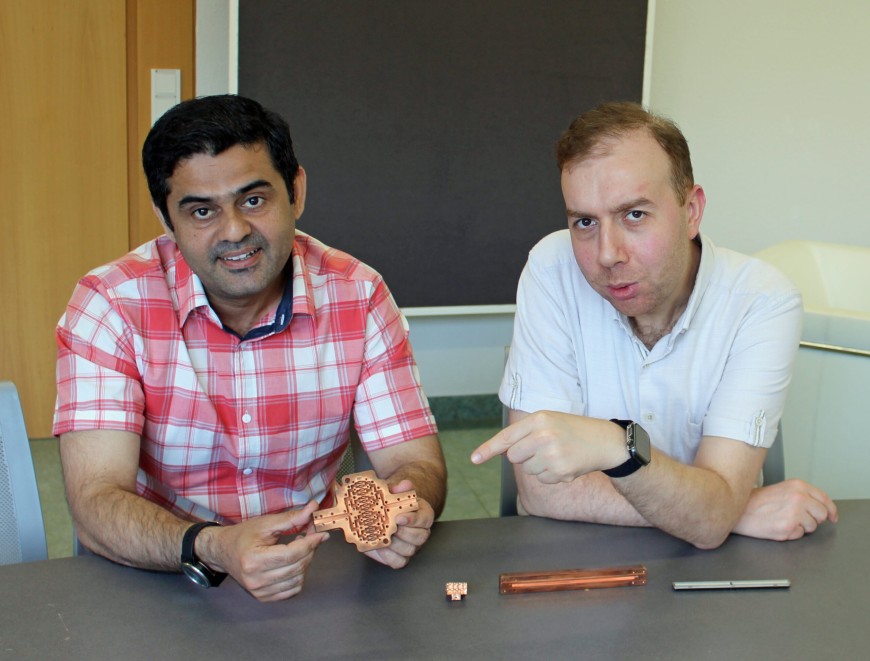

The two founders use an antenna component to demonstrate these differences: The component is usually made of aluminium. The next generation, made of a coated polymer, weighs only half as much. The third generation, which weighs around a sixth as much, is made of a glass-like material that is more resistant to temperature fluctuations. The weight of the ultra-modern ultra-light component of the fourth generation is hardly noticeable on the hand: the hollow body made of a special material mixture weighs only a fraction of its classic predecessor.

Installation without screws and bolts

In addition to the right mix of materials, design ideas are also utilised: for example, the high-frequency components made from one piece no longer need to be screwed together at Metalonn – which saves space and thickness for threads. This reduces the risk of mechanical failure, improves electrical performance and makes assembly easier. The two inventors will not reveal how they join the materials. Improving the recipe is their bread and butter. However, tests and quality checks are time-consuming and expensive.

Venture capital would be helpful and accelerating for this. The HIGHEST team gave them a lot of support, the engineers report – for example with the patent application: one patent has already been filed and a second is in the application process. Metalonn and HIGHEST invested several months of effort in applying for two funding programmes, both of which were rejected despite careful preparation and enquiries. The frustration is still palpable for the two founders – not because they were rejected, but because the information only came after precious months despite preliminary clarification. ‘For a large company, such a period of time may not count, but for a small start-up, these are crucial and precious weeks,’ emphasises Mehmood. Convincing the sponsors of state funding programmes in a detailed application and a pitch can be a challenge, and the long feedback periods can test a start-up's patience. ‘We are all the more pleased that Metalonn has taken a significant step forward with funding from BIC, a partner of the Darmstadt ecosystem,’ says Gudrun Lantelme, HIGHEST.

The application to the more US-oriented ESA start-up programme in Darmstadt was much quicker, less complicated and successful. They will also apply there for the follow-up programme, ideally together with a partner. Metalonn hopes to find an investor before the end of this year. Or a project contract: ‘We want to win customers,’ says Talan – such as satellite or drone manufacturers. To this end, they are currently focussing on ultra-light components. They also want to recruit staff to speed up development. Perhaps profits will then be possible in just one or two years.

Satellites: a market of the future

‘Companies for modern satellites in low orbits (LEO) such as SpaceX are currently revolutionising space travel – Germany should be part of this new space race,’ Mehmood demands. The future belongs to this strategic market. And the costs must fall. Currently, transport costs are ten times higher and more satellites are needed than for the usual stationary satellites in higher orbits. The service life of LEO satellites is only three to four years. Every kilogram saved therefore saves fuel and CO2 during rocket launches, says Mehmood, promoting Metalonn's (ultra)light components.

With their pioneering spirit and ambition, the two founders feel more ‘entrepreneurial’ and risk-taking than they perceive many of their fellow students to be. They believe this is probably also due to their background: Mehmood came to TUDa from Pakistan in 2007, where he completed his master's degree and doctorate on antennas made from special glass-ceramic materials. He worked at the start-up Alkan Systems for nine years. There he met Talan, who had completed his master's degree in automation technology in Turkey before coming to Germany in 2012 and working as an engineer at Ford for several years. They learnt a few things from their previous start-up: ‘Develop a product, not a technology. Don't grow too quickly. Convince investors of the idea, not the details,’ says Mehmood. The two are convinced of their expertise, their idea and their ability to realise it, and the enthusiastic reactions from experts give them a boost. They are therefore extremely confident about the future of Metalonn.

Always up-to-date with exciting news from the etit campus: Follow us on Instagram!

Recommended external content

We have selected external content from Instagram for you and would like to show it to you right here. To do this, you must reveal it with one click. You can hide the external content at any time with another click.

I agree to external content from X being shown to me. This may result in personal data being transmitted to third-party platforms. You can find more information in our Privacy Policy.