Innovative ultrasonic detection method finds air-voids in foam filled construction panels

2024/06/20 by Christoph Haugwitz

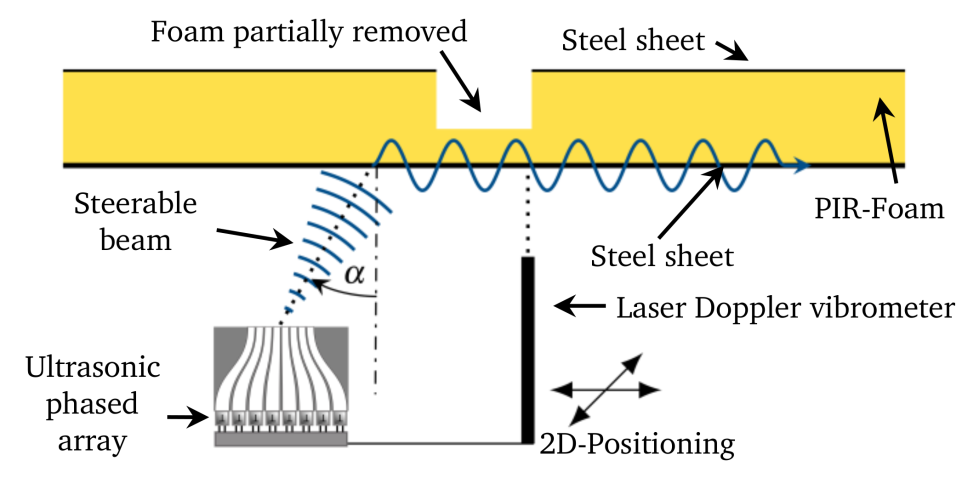

Researchers at Technische Universität Darmstadt, in collaboration with Inoson GmbH, have published a new paper in the IEEE Open Journal of Ultrasonics, Ferroelectrics, and Frequency Control. The paper, “Air-coupled Lamb Wave Testing of Buried Air-voids in Foam-filled Sandwich Panels,” introduces a novel non-destructive testing method using air-coupled Lamb waves to detect air-voids in composite sandwich panels.

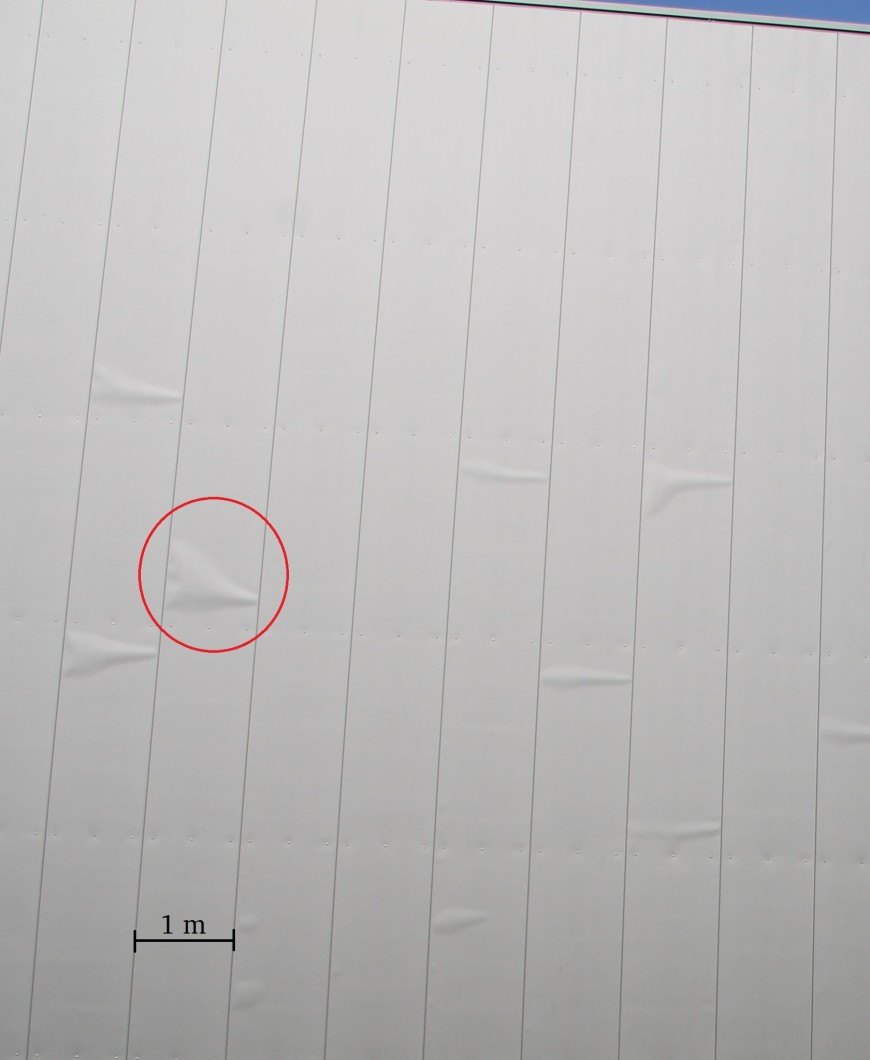

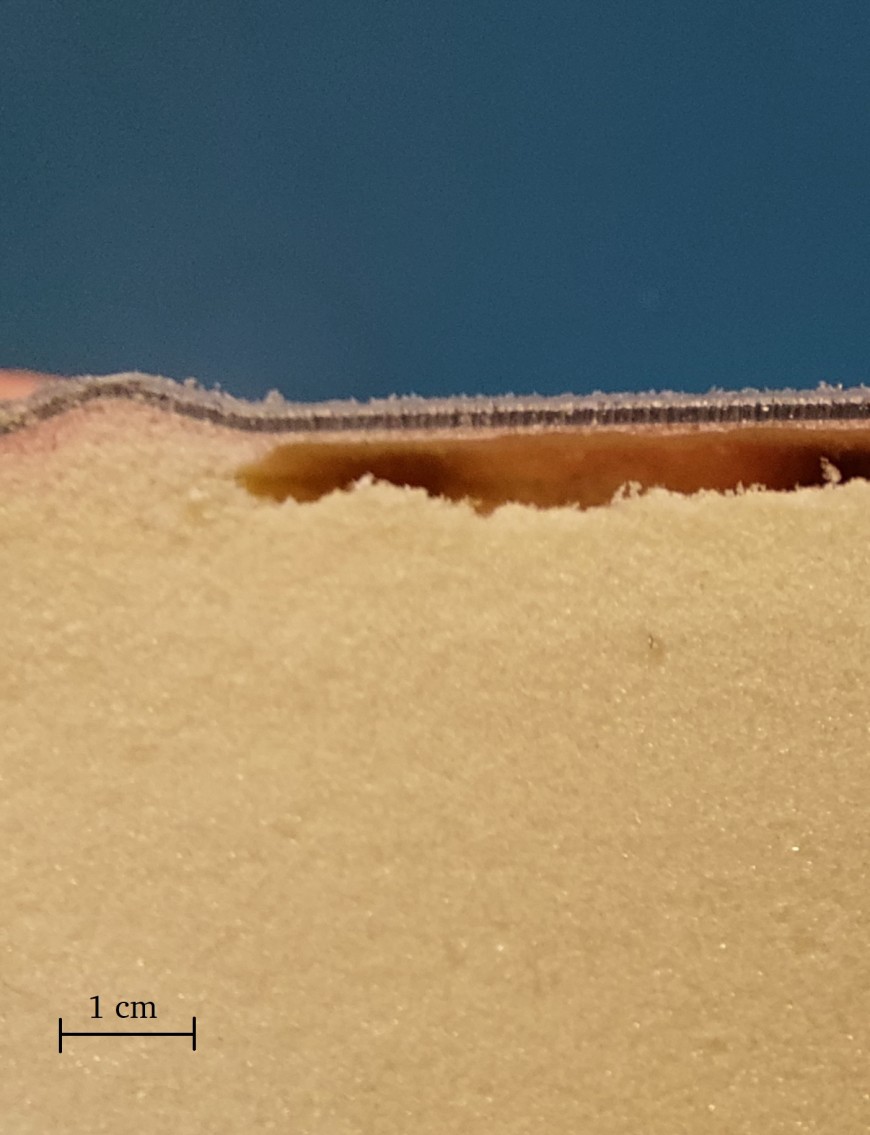

Foam-filled Sandwich panels are widely used in construction for their lightweight and cost-effective properties. However, they are susceptible to developing air-voids during manufacturing, which can grow into blisters and compromise structural integrity. Our research focuses on early detection of these voids to ensure the longevity and safety of these materials. Air-coupled ultrasonic testing has shown to be suitable for non-contact non-destructive testing.

Our team has developed an ultrasonic testing technique that employs air-coupled Lamb waves. This method allows for non-contact detection of internal air voids. We tested two setups with frequencies of 40 kHz and 200 kHz to assess their effectiveness in detecting shallow air-voids.

The 40-kHz setup penetrates up to 14 mm into the foam, while the 200-kHz setup penetrates 2.5 mm but offers better defect detection contrast. The higher frequency setup detected a 27% amplitude increase at defect sites, compared to 6% with the lower frequency.

This non-contact method shows great potential for integration into production lines, enhancing quality control and efficiency in manufacturing sandwich panels. Our findings pave the way for faster, more accurate detection of air-voids, which is crucial for improving cost-effectiveness and reducing the C02 fingerprint of these lightweight sandwich panels. The full details and methodologies are available in our published Paper.

We would like to thank the technology transfer program “TTP Lightweight Construction” of the Federal Ministry of Economics and Climate Action for funding this project (funding code: 03LB3029; Resource-efficient sandwich elements through non-destructive monitoring for lightweight construction).

For further information, please contact Christoph Haugwitz at christoph.haugwitz@tu-darmstadt.de.